Power distribution unit test equipment

New energy automobiles propose higher standard and quality requirements on connectors and power distribution equipment of new energy. The technical processes of power distribution equipment include part assembly, screw assembly, CCD test, high voltage test, air-tight test, impedance test, and strong current test.

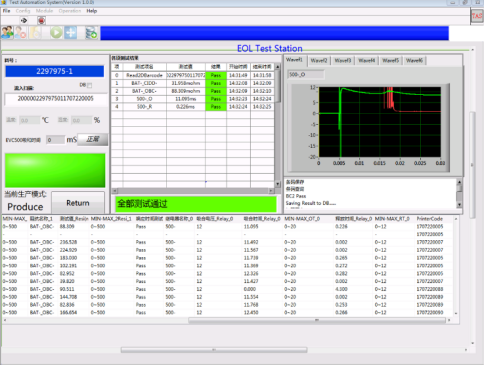

Features: 1. Whole-process guidance and monitoring on the software interface, and upload data such as position and torsion of screws assembly on the workstation. 2. Flexible production line can meet assembly test needs of products with different part numbers. 3. The server can control parameters and test items, ensuring convenient and fast switching of production standard and technique requirements. 4. The tracking function can track the production and test data of the production line, and prevent products’ jumping into another workstation. |  |

Equipment parameters:

Reference dimension: 20m* 1.5m* 1.95m

Cycle time: 160S/PC

OEE:≥90%.

Technical parameters:

Air tightness: 6PSI/45s / ≤58CC/min

Leakage current: DC 2800V / 5s / ≤10mA;

Insulation resistance: DC1000V / ≥100MΩ;

Current sensor test: 350A / ±3.5%

Resistance of precharged relay: 33Ω±5%;

Operation time of main relay: ≤20ms;

Release time of main relay: ≤12ms;